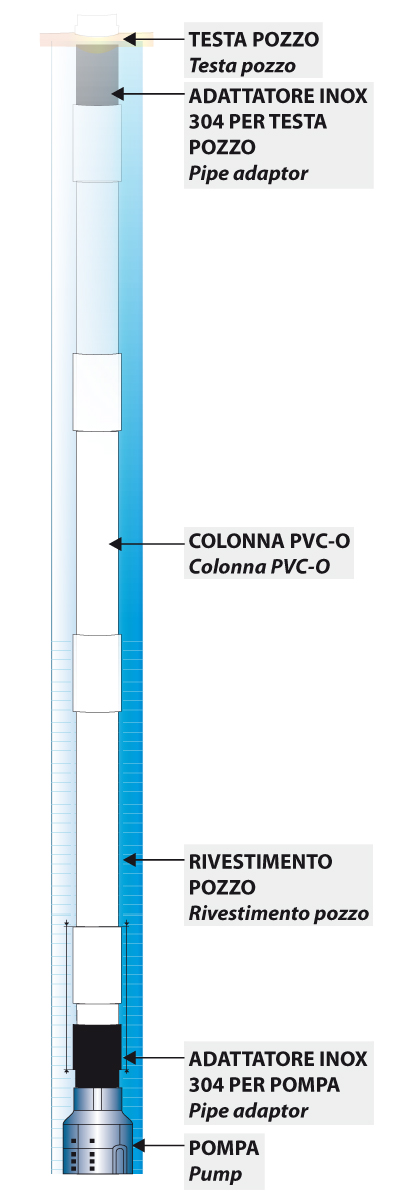

Raw material and production process

PVC-O (Orientated Polyvinylchloride)

The delivery columns are made of non-plasticised PVC-U polyvinylchloride obtained using pure, un-regenerated selected resins and without the addition of plasticisers and lubricants.

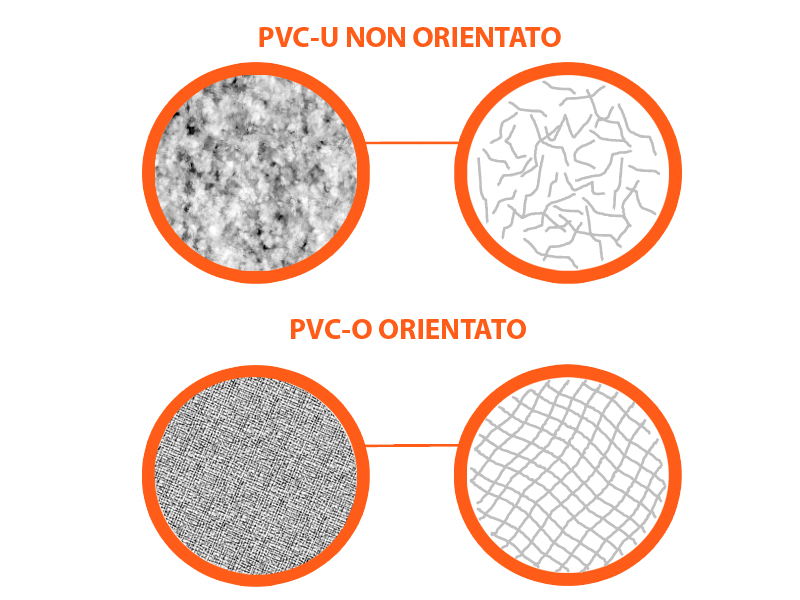

The pipes are extruded with an external diameter of around half, and with double the desired final thickness; they are subsequently heated up to the glass transition temperature and calibrated, controlling their expansion until the required dimensions have been achieved; at this phase the molecular realignment of the PVC-U occurs, becoming PVC-O.

This process imposes a well-defined arrangement on molecular chains, orientated in a circumferential and longitudinal direction, forming the structure of the laminar pipe wall, that is, a stratification of numerous “networks” formed by the bonds of the overlying molecules. This way, the mechanical aspects of the pipes increase considerably and the increase is about 60% higher than the non-orientated PVC pipes.

The pipes made of PVC-O have all the advantages of normal rigid PVC but also acquire unique mechanical characteristics that allow them to compete, in numerous applications, with normal galvanised steel pipes. Indeed, the molecular orientation produces a noticeable increase in pipe elasticity with increased resistance to shocks, a lower crack propagation capacity and greater resistance to water hammering.

This treatment also brings with it financial benefits; the pipe with the same diameter and pressure class (PN) is thinner, therefore allowing a greater flow of water and it is also lighter, resulting in reduced costs in lifting equipment and simplicity of application even in the case of larger diameters. Lastly, this process also produces a lower energy consumption compared to the production of galvanized steel pipes, thus making it a more ecological material than normal PVC-U pipes.

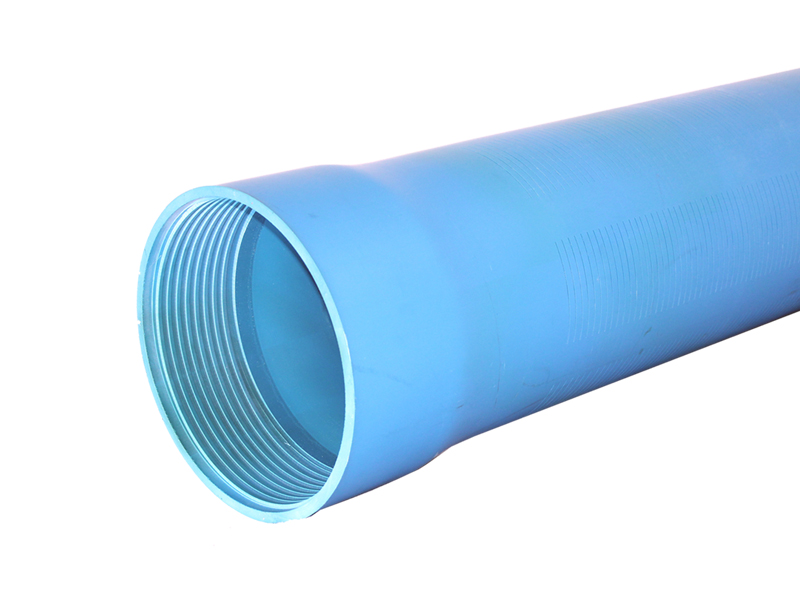

The pipes are laid using square type threaded M/F junctions and the hydraulic seal is secured by a front gasket, pre-installed in the female junction.

The conical shape of the seal means torsional vibrations of the submerged pump can be absorbed, which could cause the column to unscrew.

In order to make maintenance easier, the male threaded end has an O-ring to protect the assembled junction from the intrusion of impurities (algae or bacteria proliferation) that typically settles on the pipes submerged in the wells causing the threads to become blocked.

The ends of the pipes have an increased wall which means the male thread can be obtained without altering the resistance to pressure and traction.

| Ø external | 1" 1/4 42 mm | 1" 1/2 48 mm | 2" 60 mm | 2" 1/2 75 mm | 3" 88 mm | 4" 113 mm | 5" 140 mm |

| Ø internal | 32,0 | 36,0 | 47,0 | 61,0 | 75,0 | 96 | 118,0 |

| End thickness (mm) | 5,0 | 6,0 | 6,5 | 7,0 | 6,5 | 8,5 | 10,5 |

| Bar thickness (mm) | 4,0 | 4,9 | 4,9 | 5,4 | 4,5 | 6,4 | 7,8 |

| Ø junction (mm) | 61 | 68 | 85 | 102 | 114 | 136 | 170 |

| Bar weight (Kg) | 2,0 | 3,0 | 3,9 | 5,4 | 5,5 | 10,7 | 16,2 |

| Working pressure (Bar) | 21 | 26 | 21 | 16 | 12 | 16 | 16 |

| Maximum depth (m) | 245 | 305 | 213 | 150 | 110 | 106 | 150 |

| Recommended junction load (Kg) | 1100 | 1700 | 2100 | 3200 | 4000 | 5800 | 6000 |

Download the brochure with the product technical data sheets

Benefits

DURABILITY OF PVC is not subject to corrosion or electrolysis from salt water.

HIGH RESISTANCE Molecular orientation ensures a 60% increase 60% compared to a normal PVC pipe.

SAVING ON LAYING COSTS Quick and light system to manoeuvre and install.

HIGH YIELD Reduced loss of load, -30% compared to galvanized steel pipes

It does not require the use of gaskets and/or screws for assembly