– Carbon steel S235 – S275

– Hot-dip galvanized steel S195T

– Stainless steel EN 1.4301 AISI 304 – EN 1.4401 AISI 316

Standard delivery columns are produced with commercial pipes welded in compliance with the EN10217-7 standard; in the case of special applications, EN 10255 or ANSI B36.19 seamless (SS) pipes can be used.

The junctions are welded using MIG and TIG processes in double mode (internal and external) according to the WPQR process qualifications, performed by qualified operators and certified by TUV Italia.

The bars are supplied in standard lengths of 3 or 6 metres.

M/M threaded junctions

Supply columns with Gas M/M threaded junction with reinforced sleeve (olive)

| DN | Ø ext. Pipe (mm) | Ø ext. sleeve (mm) | Traction Resistance (ton) |

| 40 | 48,0 | 55 | - |

| 50 | 60,3 | 67 | 13,0 |

| 65 | 76,0 | 82 | 13,0 |

| 80 | 88,9 | 95 | 13,0 |

| 100 | 114,3 | 122 | 18,0 |

Flanged junctions

Commercial flanges UNI EN 1092-1

Delivery columns with flanged junctions are supplied with NBR/paper seals and appropriate 8.8, A2 and A4 nuts and bolts.

Pits can be made for the standard flanges in line with specific requirements to facilitate the passage of the pump power supply cable and guiding pipes for probes.

| DN | Ø ext. Pipe (mm) | Ø ext. Flange (mm) | Traction resistance (ton) |

| 40 | 48,0 | 140 | - |

| 50 | 60,3 | 150 | 27,2 |

| 65 | 76,0 | 165 | 27,2 |

| 80 | 88,9 | 185 | 27,2 |

| 100 | 114,3 | 200 | 36,0 |

| 125 | 139,7 | 220 | 36,0 |

| 150 | 168,3 | 250 | 45,0 |

| 200 | 219,1 | 315 | 72,0 |

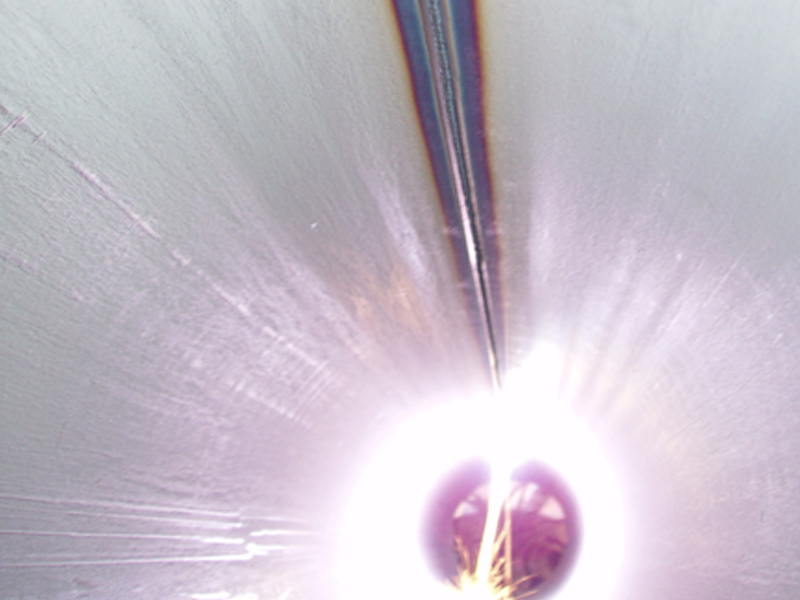

Rapid ZSM junctions

– High speed installation

– Reduced external dimensions

– Excellent hydraulic seal

The ZSM junction connection is made by inserting two AISI 316 stainless steel springs which block the axial sliding between male and female, while a laterally applied pin ensures anti-rotation.

The hydraulic seal is guaranteed by two EPDM o-rings suitable for contact with drinking water

| DN* | Ø ext. Pipe (mm) | Ø ext. Joint (mm) | Joint weight (kg) | Joint length (mm) | Traction Res. (ton) |

| 50 | 60,3 | 85 | 2,3 | 110 | 21,8 |

| 65 | 76,0 | 106 | 3,3 | 110 | 26 |

| 80 | 88,9 | 118 | 3,5 | 120 | 29 |

| 100 | 114,3 | 140 | 4,5 | 120 | 31 |

| 125 | 139,7 | 170 | 6,0 | 140 | 32 |

* sizes larger than DN125 available on request

** in the absence of internal pressure

Download the brochure with the product technical data sheets

Benefits

– High resistance

– Installation speed

– Conforms with the Ministerial Decree 174/2004 drinking water